Autoliv Explore Apps

3D and AR Solutions

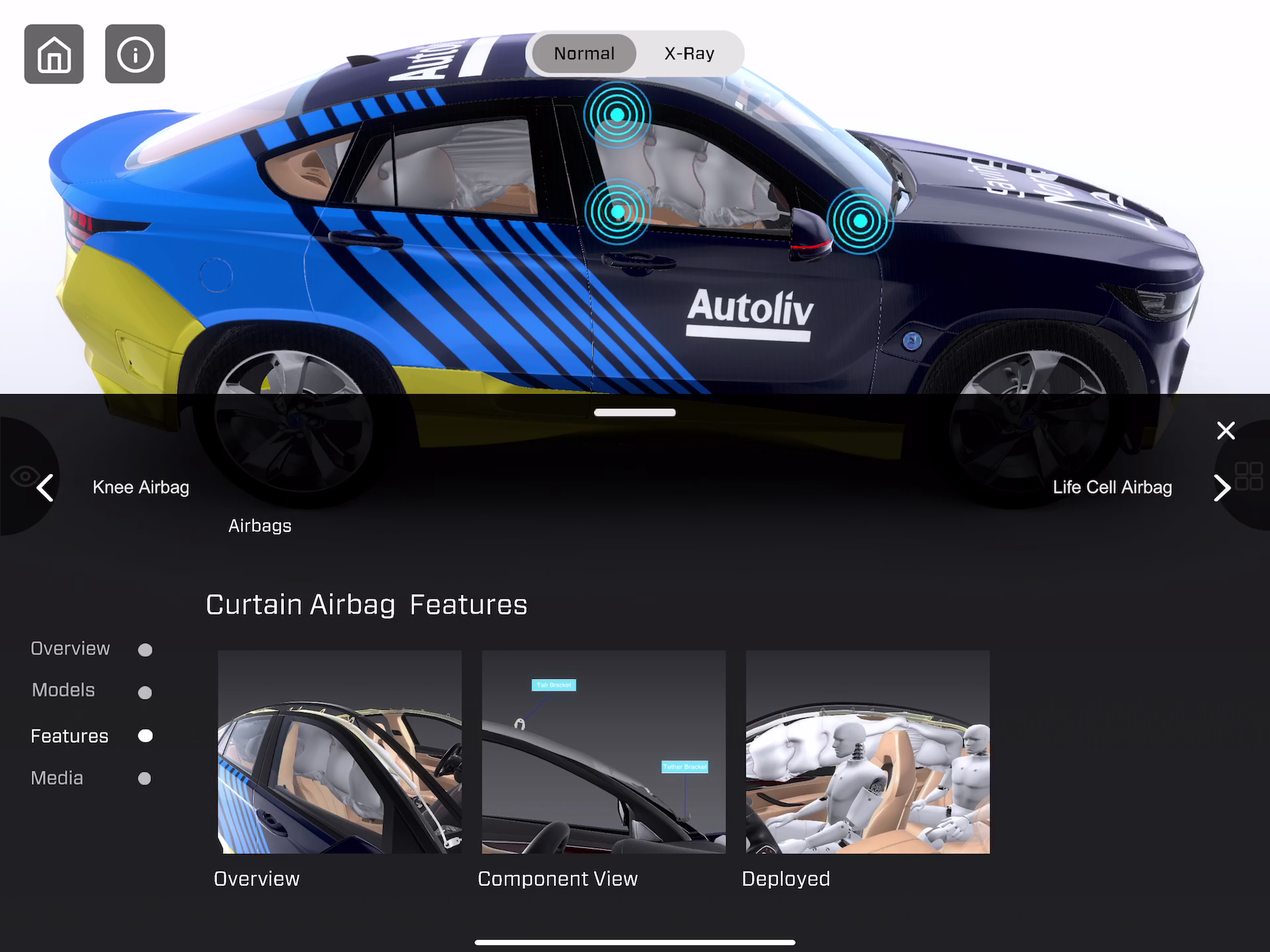

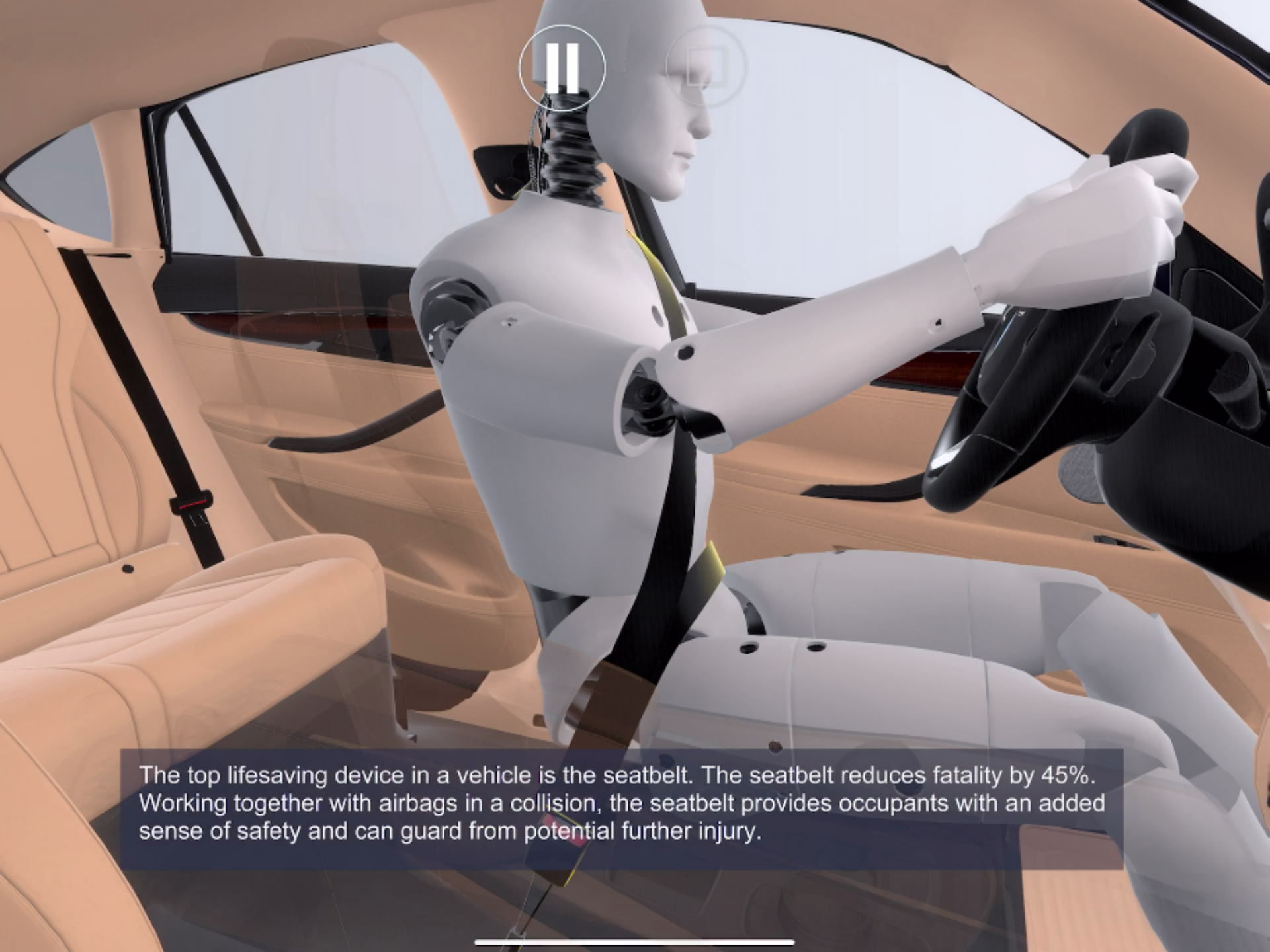

A series of immersive 3D and AR apps conceptualized and led by Vertex Motion Labs’ team member while at Cybercom Sweden, delivering advanced visualization, robust optimizations, and real-time interactivity for Autoliv’s global showcases.

Project

Case Study.

Client

Lead Partner

Specialist Partner

Executive Summary

Key Insights & Strategic Takeaways

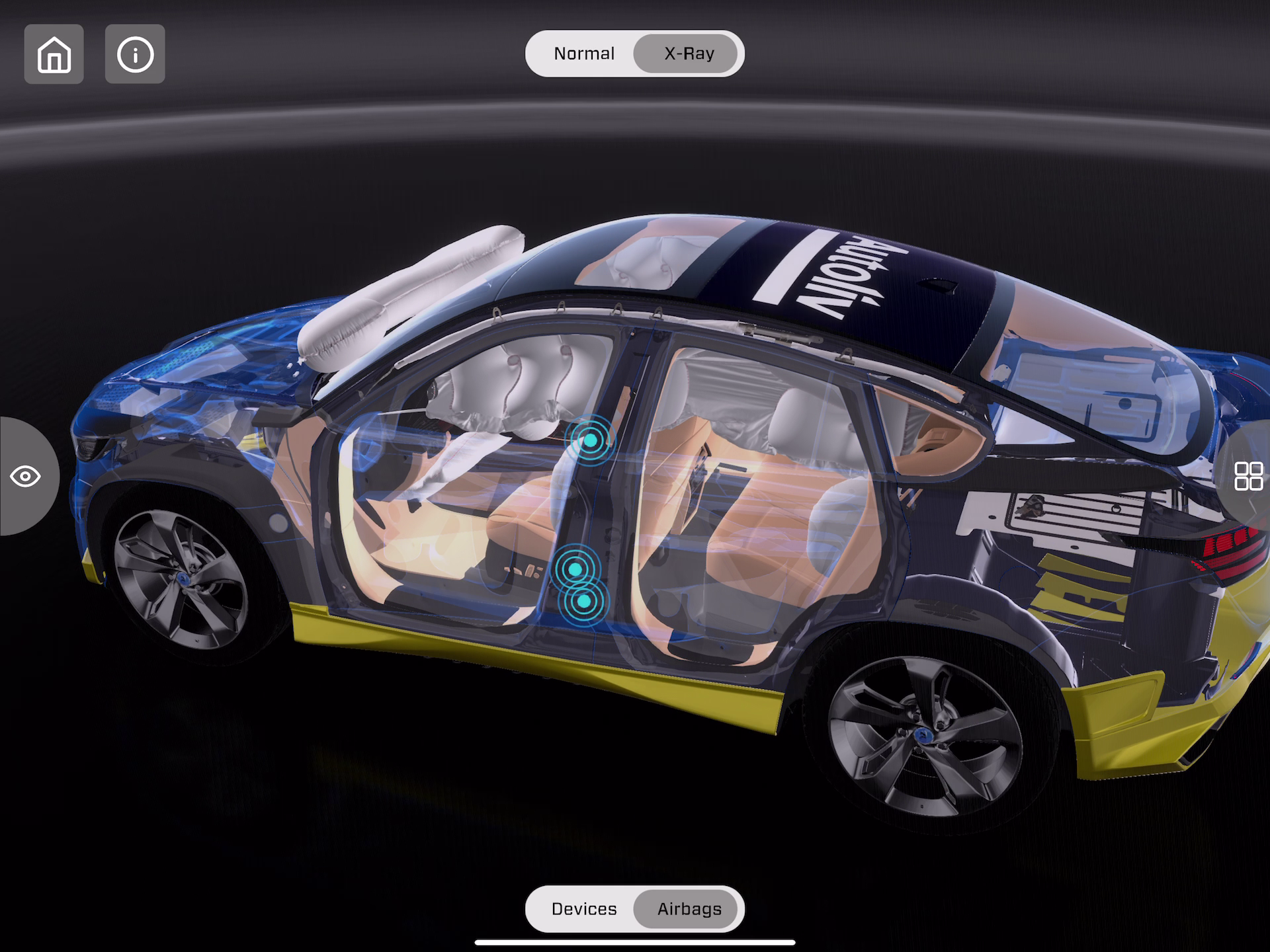

From concept pitch to globe-trotting showcase, Vertex Motion Labs (VML) helped Autoliv and Cybercom Group reimagine how the world’s largest automotive-safety supplier tells its story. Working as lead architect and project owner during more than four fast-paced releases, our team conceived Autoliv Explore – a pair of real-time 3D and AR applications that let buyers, engineers, and expo visitors dive inside a vehicle and experience Autoliv’s life-saving components in action.

The challenge was two-fold: photorealism on tablet hardware and constant reinvention for new venues. Each event (from Stockholm boardrooms to Shanghai expos and U.S. investor summits) required fresh features, richer assets, and flawless frame rates on iPad Pro. Add in multi-site teams of artists, animators, and engineers, and the project demanded both technical ingenuity and Fractional-CTO-level orchestration.

VML’s solution combined deep Unity engineering with a consulting-first mindset. We built a shared 3D/AR codebase, created “ClearVision” smart-camera logic to reveal hidden parts, and automated PiXYZ pipelines that shrank million-poly CAD models to mobile-ready meshes without losing detail. Custom Timeline tools gave animators near-cinematic control, while new UX layers allowed hundreds of expo visitors to explore simultaneously.

The impact was immediate and repeatable. Autoliv’s sales teams reported higher engagement, faster understanding of complex products, and a 30 % cut in demo-prep time. The scalable architecture let us roll out four major iterations in under 18 months, each one expanding product coverage and geographic reach. For VML, Autoliv Explore stands as a showcase of how custom software, real-time 3D, and Fractional CTO leadership can transform a traditional product demo into an unforgettable, data-driven experience.

Follow Us:

Overview

Client

Client

Lead Partner

Specialist Partner

Autoliv, a global leader in automotive safety systems.

Autoliv is a Fortune 500, Tier-1 automotive-safety giant, generating $8 billion+ in annual revenue. The company employs roughly 68,000 people across 27 countries through joint ventures, with 5,700 dedicated to R&D and engineering. Its global footprint includes 14 technical centers and 20 proving-ground test tracks, while its stock trades on the NYSE and Nasdaq Stockholm.

Industry & Region

Automotive safety, with key stakeholders across Europe, the US, and Asia (including Shanghai).

Key Objectives

-

Demonstrate Autoliv’s cutting-edge products (airbags, seatbelts, and other safety components) in an engaging, interactive 3D/AR context.

-

Optimize performance on mobile devices and iPad Pros for global expos and client demonstrations.

-

Provide a scalable codebase to support multiple iterations and expo events around the world.

Challenges

About Digit

Autoliv required an immersive, high-fidelity application that allowed users to explore detailed car interiors and see how safety components functioned in real time—both in 3D and via augmented reality. They faced several hurdles.

Technical Complexity: Achieving photorealism and high frame rates on mobile devices while rendering large, high-poly automotive parts.

Frequent Iterations: Each expo or event demanded new features, expansions, and custom AR detection methods, placing pressure on architecture.

Multi-Disciplinary Teams: The project needed designers, 3D artists, software engineers, and AR specialists spread across multiple cities and companies.

Showcasing Holographic & Interactive Elements: Required advanced camera systems and custom code to hide or render certain parts dynamically, ensuring a clear view of the safety products.Curabitur quis felis ornare mauris mattis semper. Fusce fermentum hendrerit aliquet. Sed pharetra nunc vel eros maximus, non porta enim tempus. Curabitur at condimentum nibh.

If these issues weren’t solved, Autoliv risked underwhelming expo audiences, losing out on brand impact, and dealing with unoptimized performance that could undermine the immersive experience.

Our Approach

How we do it

Over four main iterations—each building on lessons learned and new expo requirements—the lead architect and technical manager (from the VML perspective, though engaged via Cybercom Sweden) tackled the following:

Throughout these iterations, the approach combined technical leadership (project management, code architecture, optimization) with hands-on 3D and AR R&D. The emphasis on ongoing collaboration between developers, animators, and UX designers mirrored a consulting-first method, ensuring that each expo’s unique needs were proactively integrated.

Iteration 1

A custom camera system (ClearVision) was conceptualized to dynamically hide or render interior parts based on angles, ensuring unobstructed visibility of Autoliv’s safety products. A large multi-site team of 15 artists, designers, and devs was assembled. Heavy optimization techniques reduced multi-million poly car parts down to thousands of polygons, vital for iPad Pro performance.

Iteration 2

The code was re-architected to allow shared modules between 3D and AR versions. New features supported faster experimentation and flexible sprints. A fractional CTO-like oversight refined cost breakdown, negotiated new terms, and introduced a more forward-looking approach to building a robust AR app from the same codebase.

Iteration 3 - Shanghai Expo

In Shanghai, the apps gained exhibition-focused UX enhancements. Visitors interacted with 3D-printed model tags scanned by the AR app. The lead oversaw advanced animation requests from artists, customizing Unity’s Timeline, state machines, and runtime track behaviors. This enabled conditional logic and loops within the animation timeline, giving artists near “3D software-level” control inside Unity.

Iteration 4 - Autoliv CapM Event

For an event in the US (Autoliv CapM), more products were integrated into the 3D/AR apps. Automated pipelines for PiXYZ through Unity Editor were introduced to streamline importing. Additional detection options for the AR app helped manage real-size car detection and custom user interaction flows. A new lighting system and an overhauled UI allowed multiple visitors to explore the content simultaneously with consistent performance.

Results & Impact

Quantifiable Outcomes & Business Value

1. Increased Engagement: Expo audiences had an interactive, photorealistic experience exploring car components. Real-time AR detection of 3D-printed tags sparked curiosity and deeper brand recall.

2. Enhanced Performance: Frame rates on iPad Pro remained high despite rendering complex automotive meshes, thanks to strategic polygon reduction and code optimizations.

3. Scalable Codebase: By iteration 2, a shared architecture supported both 3D and AR apps. Developers could rapidly prototype new features for subsequent expos.

4. Streamlined Collaboration: The large multi-disciplinary team functioned cohesively under strong technical leadership, bridging animators’ requests with advanced Unity customizations.

5. Positive Client Feedback: Autoliv recognized the ongoing app expansions as a success, adopting new XR methods for further product showcases.

Designers & Engineers

Techs & Tools

Autoliv Explore App - driver airbag.

Image courtesy of Autoliv

The use of Autoliv Explore App in Shanghai Expo

Image courtesy of Autoliv

Insights

Top Takeaways

Fractional CTO & Consulting Mindset:

Systematic scoping, cost analysis, and architectural foresight each iteration ensured timely delivery and future reusability.

Efficient 3D & AR Workflow:

Combining robust build automation with heavy mesh optimization drastically shortened iteration cycles.

User-Focused Innovation:

Embracing novel features (like 3D-printed triggers and holographic camera angles) made each expo’s experience truly immersive, leading to repeated success across geographies.

Ongoing Iterations:

The case underscores how agile methods and a consultative approach enable continuous app evolution—vital for fast-moving expos and product expansions.

Ready for 3D & AR Solutions?

Let’s Build Together

If you want to translate complex product demos into engaging XR experiences, Vertex Motion Labs can guide your next project—fusing advanced software development with executive-level tech oversight to deliver high-impact, immersive solutions. VML blends elite dev talent and CTO insight to deliver show-stopping XR & AR solutions.